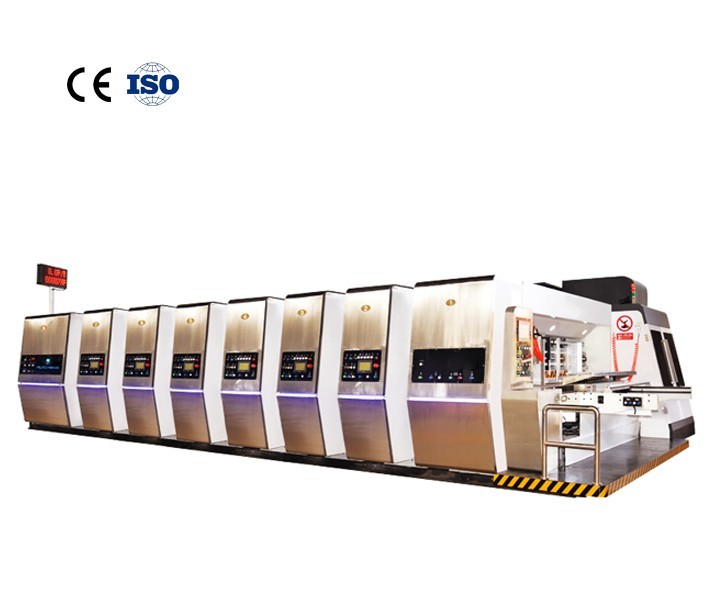

huayu Lead edge feeder colors Flexo printer slotter rotary die cutter machine/corrugated carton box printing slotting die cutting Semi-automatic corrugated carton folding machine

group namePrinting machinery

-

Min Order1 piece

brand nameJumbo Corrugated Machinery Solution

model1228

payment methodPayPal, Westem Union

-

update timeSat, 09 Oct 2021 15:38:21 GMT

Paramtents

color white

Maximum speed (piece/min) 80

Paper feeding precision (mm) ±1.0

Maximum feed size (mm) 1200x2900

Minimum feed size (mm) 350x600

Size of drawing paper (mm) 1500x2900

Maximum printing area (mm) 1200x2800

Printing set (mm) ±0.5

Thickness of standard printing plate (mm) 5mm

Minimum slotting interval (mm) Positive knife 160x160

Minimum slotting interval (mm) Scalpel 270x65

Maximum groove depth (mm) 300

Slotting accuracy (mm) ±1.5

Die cutting precision (mm) ±1.5

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Main featrues:

Paper feeding unit:

Printing unit:

Ratchet fixed roller shaft. The full version of the slotted loading and unloading plate, the electronic control of the foot switch is the opposite.

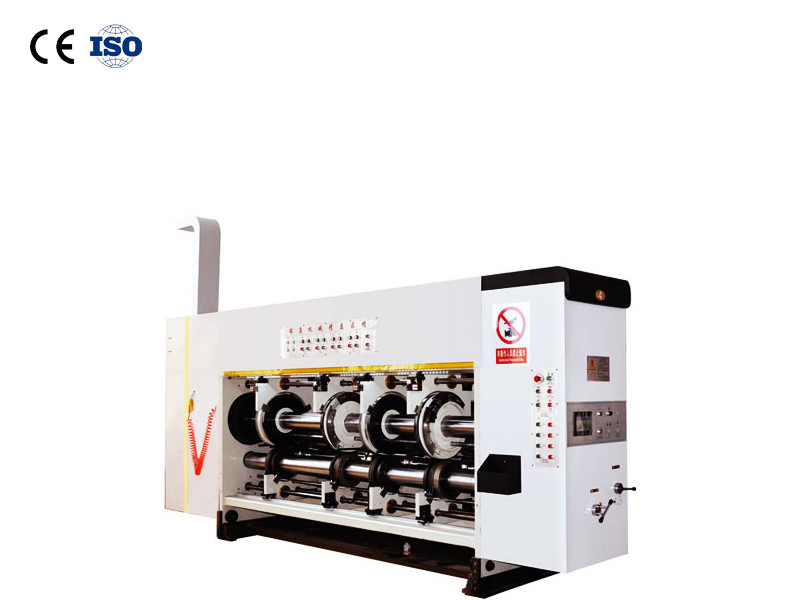

Slotting unit:

Die cutting unit:

Reply your inquiry in 24 working hours.(our normal working time:6:00~22:00)

Experienced staffs answer all your questions in time.

Customized design is available.

Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

Special discount and protection of sales are provided to our distributor.

Professional factory: We are manufacturer, specializing in producing all kinds of CNC MACHINING CENTER.

As an honest seller, we always use superior raw material, advanced processing/testing machines, skilled technicians to ensure our products to be finished in hight quality and stable feature.

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us

You need a product

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union