Explosion-Proof Dynamic Checkweigher for Hazardous Areas | SC-EP-3012L02

group nameCheckweigher

-

Min Order1 piece

brand nameSameGram

modelSC-EP-3012L02

payment methodT/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

-

update timeSat, 14 Feb 2026 20:00:08 GMT

Paramtents

Weighting range ≤200g

Weighting section size L 300mm*W 120mm

Weighting accuracy ±0.2g

Belt speed 5-90m/min

Weighting accuracy ±0.1-±0.3g

Applicable product size L≤200mm; W≤110mm

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Explosion-Proof Dynamic Checkweigher for Hazardous Areas | SC-EP-3012L02

Introduction

Explosion-Proof Dynamic Checkweigher for Hazardous Areas | SC-EP-3012L02 Features

Explosion-Proof Dynamic Checkweigher for Hazardous Areas | SC-EP-3012L02

Technical Parameters

| Product model | SC-EP-3012L02 | |

| Weighting range | ≤200g | |

Weighting section size | L 300mm*W 120mm | |

Belt speed | 5-90m/min | |

Air pressure interface | Φ8mm | |

| Case material | 304 stainless steel | |

Conveying direction | Facing the machine, left in and right out | |

Display division | 0.02g | |

| Weighting accuracy | ±0.1-±0.3g | |

| Applicable product size | L≤200mm; W≤110mm | |

Storage formula | 100 types | |

| Power supply | AC220V±10% | |

| Air source | 0.5-0.8MPa | |

Data transmission | USB data export | |

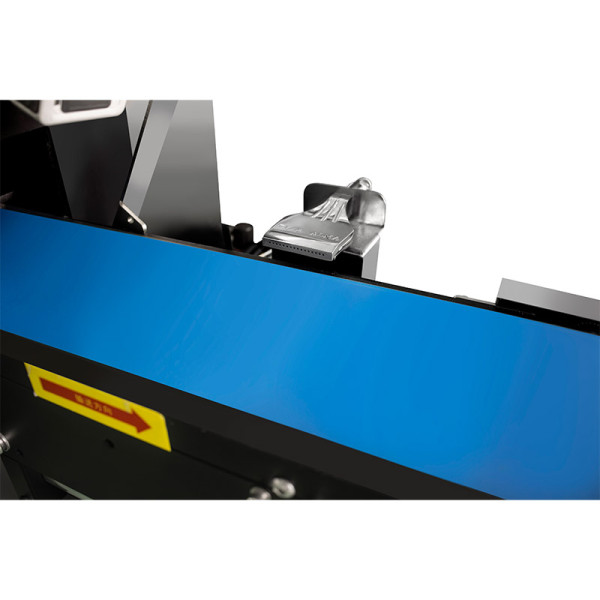

Alarm mode | Sound and light alarm and automatic rejection;Explosion-proof photoelectric switch | |

Rejection mode | Air blowing, push rod, swing arm, drop, up and down flip, etc. (customizable) | |

| Optional function | Real-time printing, code reading and sorting, online code spraying, online code reading, online labeling | |

Operation screen | 10-inch Weiluntong color touch screen | |

Control system | Sardory online weighing control system V1.0.5;Explosion-proof electrical box;Three-phase explosion-proof motor | |

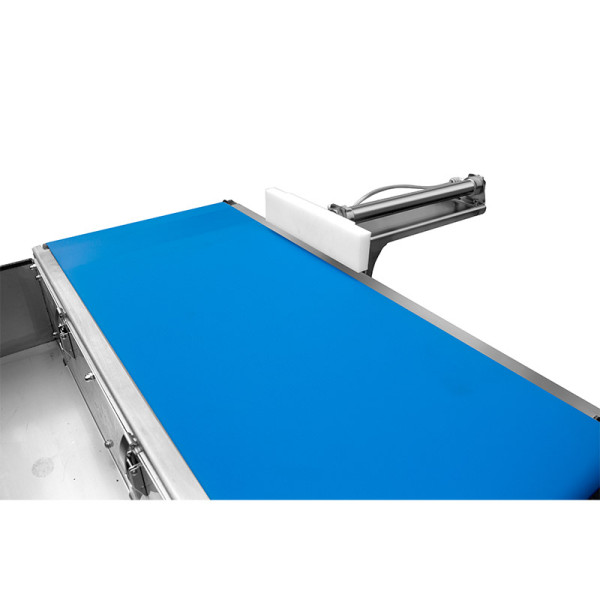

| Other configurations | Meanwell power supply, Jingyan motor, Swiss PU food conveyor belt, NSK bearing, Mettler Toledo sensor | |

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

File Downloads

What the SC-EP Explosion-Proof Checkweigher Does— Functions

Where Explosion-Proof Checkweighers Are Used— Industries & Applications

Explosion-Proof Dynamic Checkweigher for Hazardous Areas Case Studies

Complete Safety-Focused Explosion-Proof Checkweigher Support— Certifications & Customization

Certifications & Compliance — Engineering Trust and Safety Assurance

Customization & Support — Tailored Explosion-Proof Checkweigher Solutions

Explosion-Proof Belt Checkweighers for Hazardous Areas Case Studies

You need a product

You May Like

- Nearest port for product export

- shenzhen

- Delivery clauses under the trade mode

- CIP

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow