metal servo feeder automatic

group nameFeeder machine

-

Min Order1 piece

brand namekingjime

modelNCF-500

payment methodL/C, T/T

-

update timeWed, 01 Apr 2015 11:28:27 GMT

Paramtents

thickness 0.2-4.5mm

width 100-1600mm

Packging & Delivery

Min Order1 piece

Briefing

Detailed

metal servo feeder automatic

Servo driven feeds share many of the advantages with the press driven variety, such as minimal space requirement, low maintenance, and high speeds. However, servo feeds also provide benefits that press driven units cannot. The fact that they utilize a microprocessor based control gives them an added dimension. Features such as programmable move patterns, self diagnostics, auto correction, and the ability to communicate with automation - just to name a few - set them apart from other types of feeds.

Servo drives have been used for positioning applications in manufacturing for a couple of decades. The technology has matured to the point that these drives are more reliable and less expensive than they were in the past. The number of domestic and foreign manufacturers has increased dramatically in the past few years. The increased reliability, modularity, and self-diagnostic features of servo systems has done a lot to ease the fears that existed earlier, although even now it may still require a considerable degree of technical expertise to isolate some

Technical data for NCF series

1.max width:100/200300/400/500/600/700/800/1000/1300/1600mm

2.max thickness:0.2-3.2/0.3-4.5mm

3.feed length:0-9999 mm

4.feed Speed:20m/min

5. servo motor:MAX 11mm

6. Power Supply:220/380/415/440

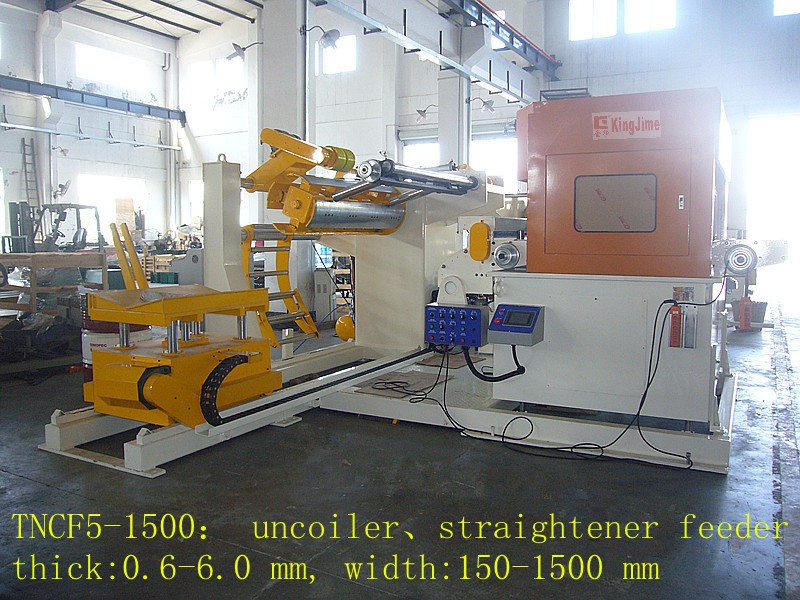

III.straightener feeder with decoiler

A automation equipment in high speed feeding coil for punch press. The machine is feeding levelling with uncoiling steel coil. The 3 in 1 whole line is controlled by PLC with computer display. We mainly apply computer-control system of brands Mitsubishi. This line can help to improve efficiency, lower cost and ensure quality. TNCF series has won wide market with its high performance and low price. The thickness of material can be from 0.2MM to 8MM, width from 150MM to 1600MM, highest precision ±0.15MM and speed 16M/min. This machine is applicable for processing of copper coil, aluminum coil, cold-rolled coil, hot rolled material, silicon steel, and stainless steel and so on.

| TNCF Standard Accessory | |||||||||

| 1.upper roller adjustment by digital watch . | |||||||||

| 2.Coil width adjusted by double handle wheel with precise screw rod . | |||||||||

| 3. Pass line can be adjusted by the lifter driven by motor . | |||||||||

| 4.Coil side guide use one set hollow rolls mechanical back gauge device. | |||||||||

| 5. Pinch roll and straightener roll material:high-strength alloy bearing steel with hard chrome plating. | |||||||||

| 6.Hydraulic coil arm device . | |||||||||

| 7.Motorized Snuber roll . | |||||||||

| 8.hydraulic guider . | |||||||||

| 9.hydraulic peeler table . | |||||||||

| 10.Mitsubishi PLC control feeding program from Japan . | |||||||||

| 11.Feed accuracy controlled by Japan YASKAWA servo motor with precise planetary reducer . |

You need a product

You May Like

- Nearest port for product export

- shenzhen

- Delivery clauses under the trade mode

- FOB, CIF

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right