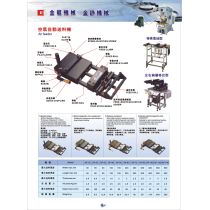

steel coil feeder

group nameFeeder machine

-

Min Order1 piece

brand namekingjime

modelNCF-300

payment methodL/C, T/T

-

update timeMon, 15 Jun 2015 15:05:31 GMT

Paramtents

product name steel coil feeder

Packging & Delivery

Min Order1 piece

Briefing

1.NC Servo feeding. Operating with Computerize Numerical Control by ...

Detailed

2.High precision feeding: to meet the coming of hi-tech industry, controlled by computer closed circuit feedback system to keep precision degree within +/-0.15mm

3.Feeding function: input 20 sets of different feed length, each group provides 999 times for punching or cutting to satisfy processing of special products.

4.High efficiency release device, match with adjustment of signal from the cutter or press machine through cable wire.

5.Setting of feed length: directly input feed length on the control plate, and then it can reach needed distance, feed length max 9999.99mm. speed max 100m/min

Features

1.3 in 1 uncoiler and straightener saves space and increase productivity.

2. Straightener and thickness adjustment by 4 worm gear micro-adjuster withreading 0.1mm advance reference indicator.

3.Feed and straightener roll with a hard chrome plated.

4.High rigid mechanical design sturdy construction, and high power output to secure proper straightening and feeding during the speed increasing efficiency.

5.Electric loop control system.

6. Hold down arm device

7.Inverse curve roll, easy to set up the curve up or down of feeding exit direction.

8.Feeding line easily adjusted by advance worm gear screw Jacks device.9.Coil Material Entry support Assembly can bring the material into pinch rollers Automatically to save man power and increase safety,

10.Coil side guide.

11.Outgoing catenary to assist and support the material12.A Clusster gear set maximizes transmission of horse power.

13.Transformer

| Item/Model | TNCF2-300 | TNCF2-400 | TNCF2-500 | TNCF2-600 | TNCF2-700 | TNCF2-800 |

| Width of Material(mm) | 75-300 | 75-400 | 75-500 | 75-600 | 75-700 | 75-800 |

| Thickness of Material(mm) | 0.3-2.3 | |||||

| Max.coil Weight(kg) | 2T weight can be customized | 3T weight can be customized | 5T weight can be customized | |||

| Coil L.D.(mm) | 508 | |||||

| Max.Coil O.D.(mm) | 1200 | |||||

| Max.Speed(m/min) | 16 | |||||

| Feed Pitch Accuracy(mm) | ±0.15 | |||||

| Feed ROLL | Upper1 / Lower1 | |||||

| Straighten ROLL | Upper5 / Lower4 | |||||

| Voltage | 380VAC / 60Hz | |||||

| Air power supply | 5kg / CM² | |||||

| Uncoiler Expansion | Hydraulic | |||||

| Servo Motor(kw) | AC1.8() | AC2.9() | ||||

| Uncoiler Motor(kw) | 1.5 KW | 2.2 KW | ||||

| Coil Car | optional | |||||

| Pass line | ±100 MM | |||||

| Model/Width/Thickness | 0.3 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | 2 | 2.3 |

| TNCF2-300 | 300 | 250 | 220 | 180 | ||||

| TNCF2-400 | 400 | 300 | 250 | 220 | 180 | |||

| TNCF2-500 | 500 | 400 | 300 | 250 | 220 | 180 | ||

| TNCF2-600 | 600 | 500 | 400 | 300 | 250 | 220 | 180 | |

| TNCF2-700 | 700 | 600 | 400 | 300 | 250 | 220 | 180 | |

| TNCF2-800 | 800 | 600 | 400 | 300 | 250 | 220 | 180 | |

You need a product

You May Like

- Nearest port for product export

- shenzhen

- Delivery clauses under the trade mode

- FOB, CIF

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right